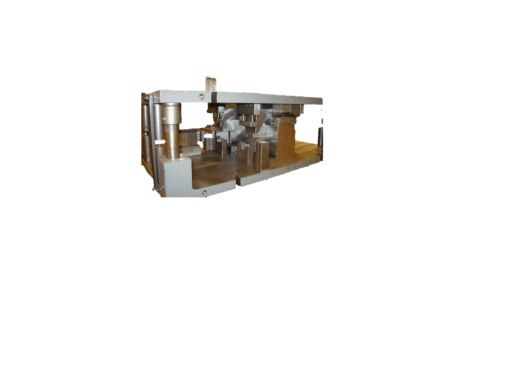

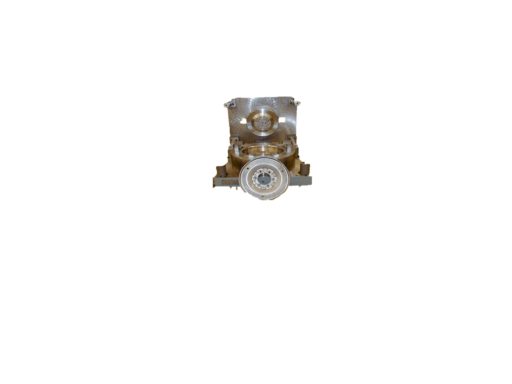

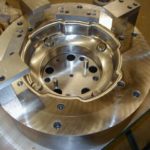

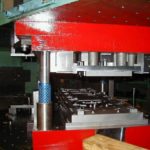

Dies are tools used in a press to make finished parts with a wide variety of operations including: blanking, bending, extruding, forming, piercing, and trimming. Unlike a progressive die, dies work typically with one hit of the press and not with coil fed material getting multiple strokes. Raw material or material with operations already preformed on it can be placed into the die. When the press closes, the work is performed on the part, and when the press opens, the part is removed and another part is put in. Dies can have multiple stations, but typically rely on the operator to move the part from one operation to the next.

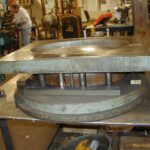

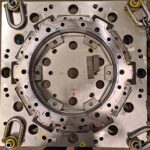

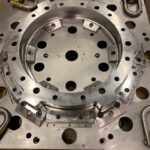

Schoitz Engineering uses the latest in 3D technology and CNC machining to ensure our dies make accurate parts time and time again. We use extremely durable tool steel proven to withstand the force needed to hold-up over time, and when possible, purchased components for quick and easy die maintenance when necessary. All dies are tested and inspected in house to part print dimensions so when they arrive at your facility, they make good parts the very first run. Below are a few die samples we have produced at Schoitz Engineering.