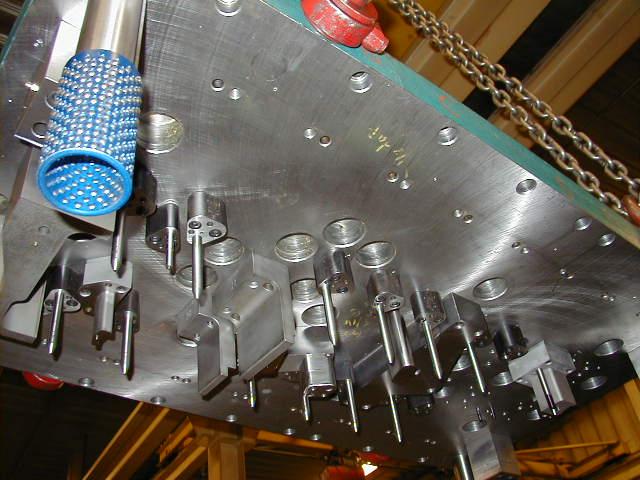

A progressive die is a tool built to create a finished part from a strip of raw material. Progressive dies are placed into a press and the raw material is fed into one end. As the press opens, the material is moved forward with feeders a precise distance. When the press closes, the work to the raw material is preformed. This work can include: bending, coining, punching, and cutting. The raw material progresses through the die performing different tasks at each station until a finished part is ejected as the end result.

Schoitz Engineering prides ourselves on our quality of progressive die-making. Our progressive dies are made from extremely durable tool steel proven to withstand the force needed to hold-up over time. Our progressive dies are tested and inspected in house to part print dimensions so when they arrive at your facility, they make good parts the very first run. Below are a few samples of progressive dies we have produced at Schoitz Engineering.